Back to BisDent Globe Articles

BISCO: Creating Solutions to Clinical Challenges! Bonding to Zirconia, Alumina and Metal with Z-PRIME™ Plus

Zirconia; the Future of Aesthetic Indirect Restorative Dentistry?

Submitted by: Dr. Douglas Brown

Zirconia-based restorations and reinforced glass ceramics are the fastest growing segment in the North American laboratory market. Zirconia’s high strength and fracture toughness are two of its unique advantages compared to current glass filled ceramic systems. Zirconia has a flexural strength (900-1100 MPa) that is 5x greater than current ceramics; 2x as strong as alumina, and 3x as strong as e.max lithium disilicates. Combined with a fracture toughness of 8-10 MPa (2x greater than alumina) and the ability to “transformational toughen”, zirconia can now be considered a universal indirect restorative material.

The computer-aided design/manufacturing (CAD/CAM) technology, together with excellent mechanical and aesthetic qualities, has expanded the clinical use of zirconia to include aesthetic conservative restorations and long span restorations. In addition, zirconia’s hard and dense surface is ideal for resisting wear damage to opposing dentition and making zirconia an attractive material for dental restorations. The applications of zirconia (e.g. Lava, 3M ESPE; Cercon, Dentsply; Procera, Nobel Biocare) in dentistry include: endodontic posts, implants, implant abutments, orthodontic brackets, cores for crowns, and fixed partial denture prosthesis frameworks.

Zirconia Demands Adhesion

The use of Zirconia in conservative aesthetic dentistry in combination with short, non-retentive preparation designs commonly seen in today’s complex restorative cases demands that chemistry be created to allow development of adhesive primers, specific to oxide-based materials. This chemistry enhances the adhesion between hydrophobic resin composites/cements and indirect oxide-based substrates (zirconia, alumina, metal). BISCO’s goal was to create a cohesive interface between the zirconia and resin cement, improve initial bond strengths capable of resisting hydrolytic degradation, and allow for the use of stronger and more durable resin cements.

Addressing the Needs of the Individual Substrates

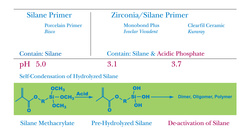

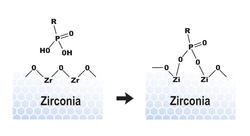

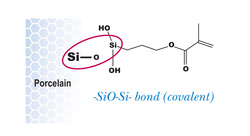

The key to optimizing adhesive performance and durability is in understanding that enamel and dentin are alive…. and zirconia, alumina, metal and glass are dead! Manufacturers who state that “one product does all bonding” are not following the science…they are marketing products! Enamel and dentin require adhesives that create micro-retention and infiltrate, such as ALL-BOND SE® and ALL-BOND 3® from BISCO. Oxide-based indirect substrates require primers with phosphate co-monomers to covalently bond to the oxide (Z-PRIME Plus). Glass porcelains require silane to interact with silica in glass to form siloxane (BIS-SILANE™, Porcelain Primer) (see Figure 1). Cohesively recreating the lost fibrous DEJ between dentin/enamel and the primed indirect substrate are luting cements that should be hydrophobic, stable upon aging and have self-cure modes that are proven.

Figure 1: Oxide-based indirect substrates require primers with

phosphate co-monomers to ionically bond.

Finding the solution to Zirconia Bonding begins with an understanding of adhesive interfaces. The gold standard in luting cements are hydrophobic resin cements (DUO-LINK™, BISCO). Unfortunately hydrophobic cements do not naturally adhere to oxides, and require a primer to create a cohesive interface. Traditionally, zirconia bonding incorporated the use of self-adhesive resin cements (BisCem®, BISCO) or glass ionomer cements. Phosphate monomers within self-adhesive cements do have a mild affinity for zirconia oxide and can be used with confidence in retentive preparation designs, but unfortunately these categories of cements are known to be physically weaker. Creating simple adhesive systems that allow for the use of hydrophobic resin cements that work synergistically to improve retention is possible (DUO-LINK SE, BISCO).

Primers for Oxide-Based Substrates versus Glass Porcelain Substrates

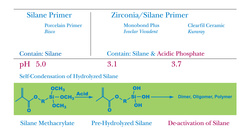

Silane is the Achilles heel of Clearfil Ceramic Primer (Kuraray) and Monobond Plus (Ivoclar/Vivadent). The research of Dr. Byoung Suh and others confirm that the use of Silane (BIS-SILANE, Porcelain Primer) in conjunction with micro-mechanical retention from HF acid or sandblasting is the gold standard of protocols addressing glass indirect substrates including lithium disilicates (e.max), reinforced porcelain and feldspathic porcelain. Stability of silane is dependent upon pH of the mixture and requires special attention by the manufacturer. Recently Clearfil Ceramic Primer and MonoBond Plus were introduced to the dentist and touted as “one primer for both glass and oxide-containing indirect substrates”. BISCO’s research proves that this statement is scientifically incorrect. Both Clearfil Ceramic and MonoBond Plus contain silane in addition to a phosphate monomer, but the combination of these two require a pH that causes silane to become unstable, resulting in hydrolysis and a significant loss of bond strength to porcelain and lithium disilicate (Figure 2).

Figure 2: To maintain a good shelf-life, pH of one-bottle silane

primer systems should be adjusted to 4-5.

Optimizing adhesive performance to Lithium Disilicate (e.max) and glass-based porcelains, BISCO offers BIS-SILANE (2 bottle) or Porcelain Primer (1 bottle), specifically made to address glass substrates without the incorporation of phosphate monomers. Coupled with the use of BISCO’s Porcelain Etchant (4% or 9.5% HF) the clinician can have confidence in predictable bonding to glass substrates (Figure 3).

Figure 3: Combination of silane and phosphate monomer

reduce bond strengths to Lithium Disilicate.

Adhesion to Zirconia Has Now Been Redefined

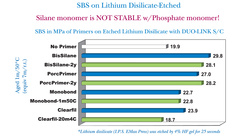

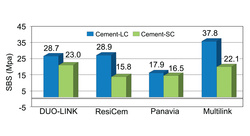

Through exhaustive research, BISCO has uncovered the formula that allows for cohesive adhesion to oxide-based materials (Figure 4). Research supports the fact that MDP phosphate monomers contribute to long-term durable bonding to zirconia, while silane does not contribute to zirconia (oxide) adhesion. BISCO, in a proprietary formula, combined both phosphate and carboxylic monomers to create a stable, adhesive formula. Silane was not incorporated, which allows for greater concentrations of phosphate monomer that research shows promotes zirconia adhesion and provides stability in the formula. The proprietary combination of two proven adhesive monomers results in a “first of its kind” primer (Z-PRIME Plus) for adhesion to zirconia, alumina and metal (Figure 5). In addition, the co-monomers enhance the effectiveness of competitor cements over own primers! (Figure 6).

Figure 4: Cohesive adhesion to

oxide-based materials.

Figure 5: Z-PRIME Plus significantly increases adhesion to

zirconia, alumina and metal.

Figure 6: Z-PRIME Plus significantly enhances the bond

strength of other resin cements.

DUO-LINK with “Catalyst Activated Technology”

The weakest link in cementation of indirect substrates should not be the luting cement. With Z-PRIME Plus, hydrophobic resin cements (such as DUO-LINK) can be used. The traditional use of weaker self-adhesive cements (including glass ionomers) can now be improved. Additionally, a dual-cured cement is preferred over a light-cured only cement, removing the potential for limited light transmission through opaque zirconia, alumina and metal copings. However it is important to note that all dual-cured cements are not created equal. Finding a dual-cured cement that performs equally well in both light-cured and self-cured modes, is not affected by aging, and has an appropriate (and accurate) setting time can be a challenge. Resin cements that fully polymerize in the self-cured mode within six minutes allows for interproximal flossing, whereas one that sets in 10 to 12 minutes requires careful and appropriate measures not to interfere with the bonding we are trying to create.

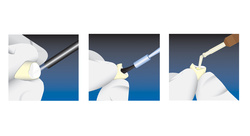

Optimizing Adhesive Performance to Zirconia, Alumina and Metal Oxides The ideal protocol for luting a zirconia, alumina or metal crown in conservative or non-retentive conditions: (see Figures 7 and 8)

-

Treat the dentin and enamel surface with a bonding agent (ALL-BOND 3 or ALL-BOND SE),

-

Treat the zirconia, alumina or metal internal surface with Z-PRIME Plus

-

Apply hydrophobic resin cement (DUO-LINK)

This combination creates a linked cohesive/hydrophilic seal between tooth and the indirect restoration. In preparations with adequate retention/resistance form, self-adhesive resin cements like BisCem can be used. BisCem contains hydrophilic phosphate monomers and bonds to zirconia as well as to the dentin/enamel substrate. Bond strengths are lower (10-12 MPa), but in retentive preparations, the ease of placement is a compelling benefit. However, Z-PRIME Plus can be used with self-adhesive resin cements like BisCem to double the bond of self-adhesive cements to zirconia, alumina and metal.

Figure 7: Short/tapered, non-retentive Zirconia crown

adhesively bond with resin cement.

Figure 8: Clean the internal surface of the restoration; rinse and air dry. Apply 1-2 coats of

Z-PRIME Plus, uniformly wetting the internal surface. Dry with an air syringe for 3-5 seconds. Proceed with cementation using a luting cement such as DUO-LINK.

BISCO: Bringing Science to the Art of Dentistry

Adhesion is Our Passion… it is our commitment to you, the oral health professional. We understand that it is the Dentists Profession and BISCO is committed to creating solutions to your clinical challenges. We appreciate the opportunity to partner with you in providing oral health solutions are proud that you trust BISCO to provide you with all of your adhesive needs.

March 2010 BisDent Globe, Volume XIV, Issue I

Back to BisDent Globe Articles